Pallet Conveyor System Box Conveyor System

Project Background

With the rapid development of e-commerce and the retail industry, a well-known retail enterprise faced immense pressure to improve its warehousing and logistics efficiency. To cope with the growing order volume and diverse product demands, the company decided to implement a smart warehouse logistics system to achieve efficient inventory management and order processing. After detailed market research and technical evaluation, the enterprise chose to collaborate with a smart logistics integrator to execute a new smart warehouse logistics project. Our company served as the conveyor equipment supplier for the integrator, collaborating closely to successfully complete this project.

Xijiao village, Huanxiu Ban Shi Chu, Jimo District,Qingdao.

+(86) 13325001090

Solution

Ssohou Company provided a comprehensive smart warehouse logistics solution for the retail enterprise, comprising the following core modules:

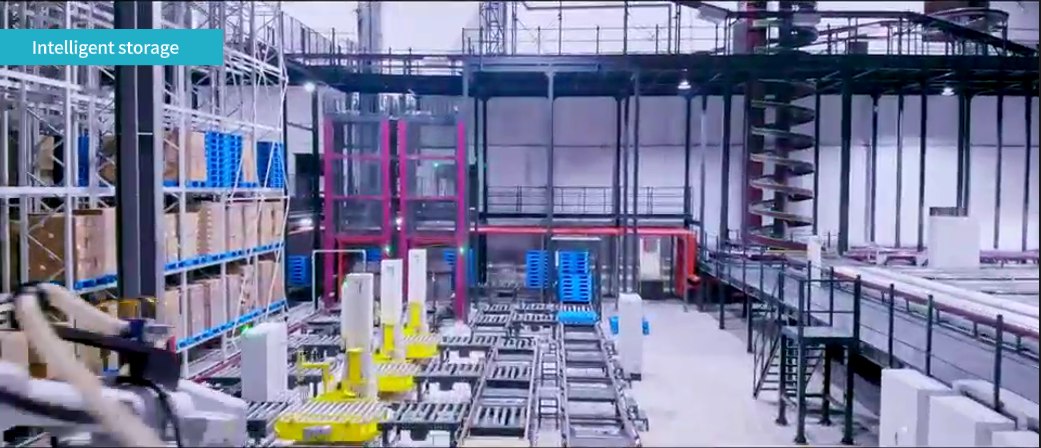

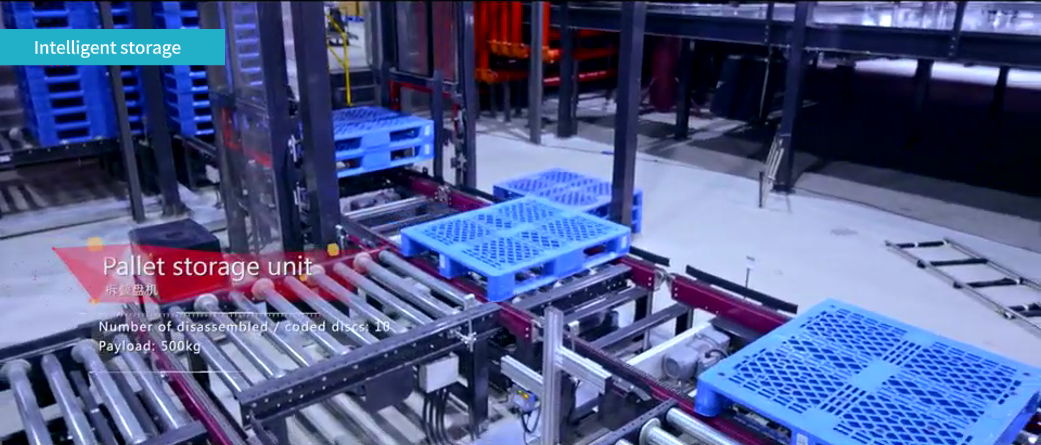

Pallet Conveyor System: Utilizing equipment such as chain conveyors, roller conveyors, transfer machines, elevators, and stretch wrapping machines, this system achieved automated transport of pallets within the warehouse. The pallet conveyor system seamlessly integrated with ASRS, ensuring efficient circulation of goods within the warehouse.

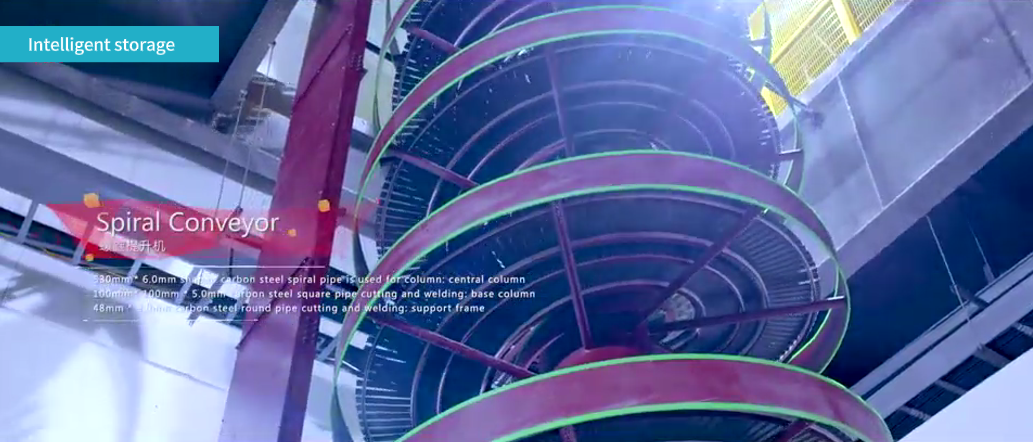

Box Conveyor System: Designed for the rapid transfer and sorting of small items. This system integrated intelligent sorting technology using equipment such as transfer machines, belt conveyors, roller conveyors, and spiral elevators to accurately deliver various types of products to sorting stations according to order requirements.

Solution

Ssohou Company provided a comprehensive smart warehouse logistics solution for the retail enterprise, encompassing the following core modules:

Automated Storage and Retrieval System (ASRS): Utilizing high-density storage racks and automated stacker cranes, this system facilitated efficient handling of goods. The system automatically completed inbound and outbound operations based on order requirements.

Pallet Conveyor System: Through automated guided vehicles (AGVs) and conveyor belt systems, this system enabled automatic transport of pallets within the warehouse. Seamless integration with ASRS ensured efficient circulation of goods within the warehouse.

Box Conveyor System: Designed for the rapid transfer and sorting of small items. This system integrated intelligent sorting technology using equipment such as transfer machines, belt conveyors, roller conveyors, and spiral elevators to accurately deliver various types of products to sorting stations based on order requirements.

Warehouse Management System (WMS): Employing RFID and barcode technology, this system enabled end-to-end tracking and management of goods. WMS integration with the enterprise's ERP system ensured real-time data updates and sharing.

Technical Specifications

- Automated Storage and Retrieval System (ASRS):

- Storage Capacity: 5000 pallet positions

- Stacker Crane Speed: 60 meters/minute

- Maximum Load: 1000 kg/pallet

- Pallet Conveyor System:

- Conveying Speed: 30 meters/minute

- Maximum Load: 800 kg/pallet

- Box Conveyor System:

- Sorting Speed: 1200 items/hour

- Transfer Speed: 45 meters/minute

- Warehouse Management System (WMS):

- Data Update Frequency: Real-time

- Supported Devices: RFID readers, barcode scanners

Project Implementation

Needs Analysis: In-depth discussions with the customer to understand specific requirements and warehouse environment, followed by detailed project planning.

System Design: Based on customer needs, Ssohou Company's technical team designed the overall smart warehouse logistics system solution, including equipment selection, layout design, and system integration.

Equipment Manufacturing and Installation: Manufacturing of equipment as per design specifications, followed by professional installation and commissioning by skilled technicians.

System Integration and Testing: Integration of subsystems into the Warehouse Management System (WMS) and comprehensive testing to ensure functionality and performance.

Training and Maintenance: Provision of system operation training and equipment maintenance guidelines to ensure proficient use and upkeep by operators.

Project Outcomes

Following the implementation of Ssohou Company's smart warehouse logistics system, the retail enterprise experienced significant improvements in overall warehouse and logistics efficiency:

Processing Efficiency: Order processing time reduced by 40%, significantly enhancing customer satisfaction.

Inventory Management: Inventory turnover rate increased by 30%, reducing backlog and minimizing goods loss.

Space Utilization: Warehouse space utilization improved by 25%, facilitating efficient warehouse operations.

Operating Costs: Introduction of the automated system reduced labor costs and operational expenses.

Customer Feedback

The retail enterprise provided high praise for Ssohou Company's smart warehouse logistics solution, noting its stable performance, ease of operation, and comprehensive service. The customer expressed intent to continue collaborating with Ssohou Company to further enhance their warehouse and logistics management capabilities.

Conclusion

Ssohou Company's smart warehouse logistics solution effectively enhanced the customer's warehouse and logistics efficiency through advanced automation technology and intelligent management systems. Moving forward, Ssohou Company remains committed to technological innovation and service optimization, aiming to provide more enterprises with efficient and reliable smart warehouse logistics solutions.