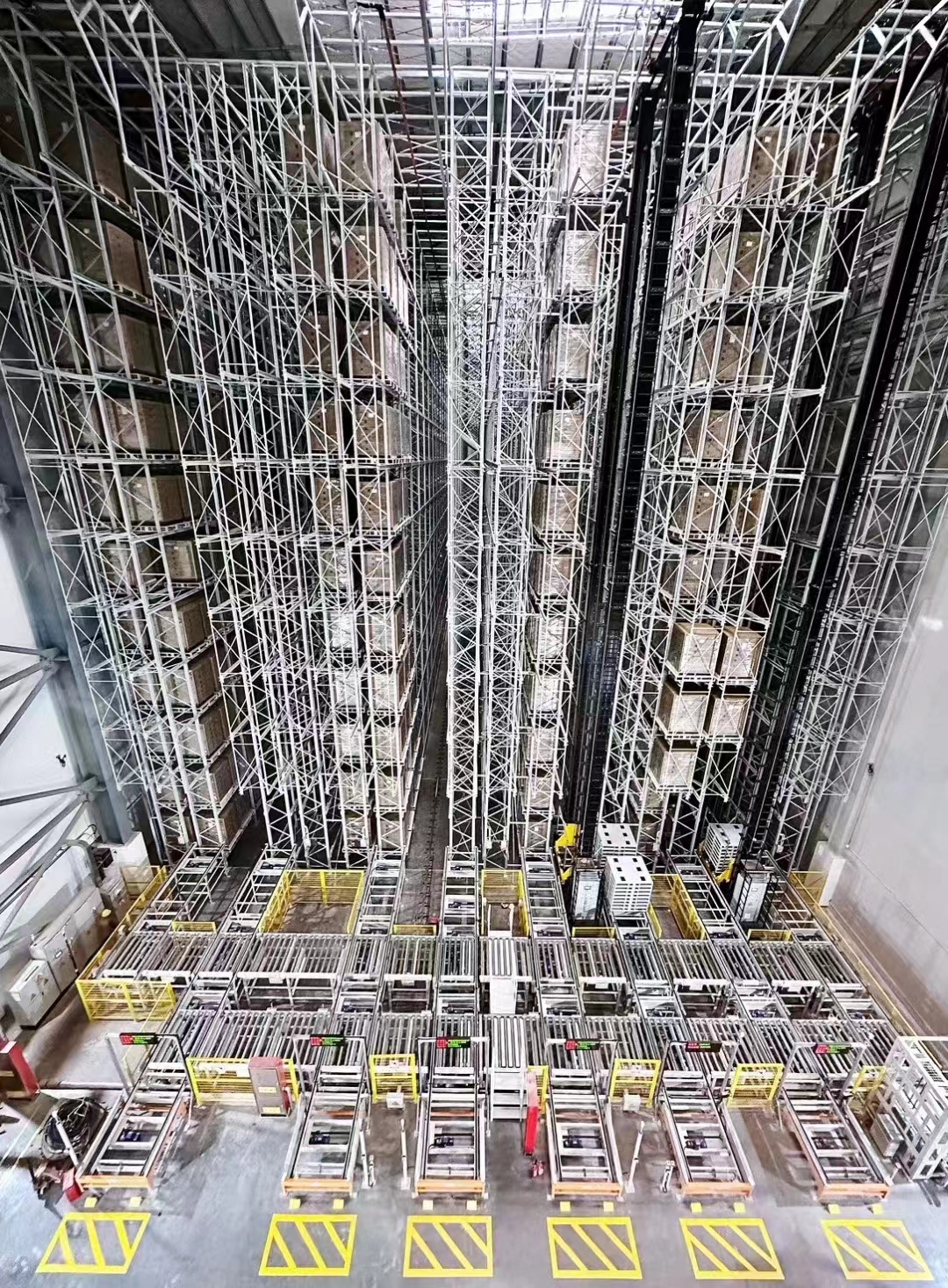

Smart warehouse pallet conveying project case

Project Case Study: Equipment Integration in Material Handling System

Project Background

In response to the increasing demands of efficient material handling and logistics, a leading logistics solutions provider collaborated with a major manufacturing facility to enhance their warehouse operations. The goal was to streamline the movement of goods within the facility and improve overall operational efficiency. After thorough assessment and consultation, our company was selected to design and integrate a tailored material handling system.

What's App:+(86) 13325001090

Solution Overview

Our solution incorporated advanced equipment to optimize material handling processes:

Chain Conveyor System: Implemented to ensure continuous and reliable transport of goods within the warehouse. The chain conveyor system efficiently moves products along designated paths, facilitating smooth workflow and reducing manual handling.

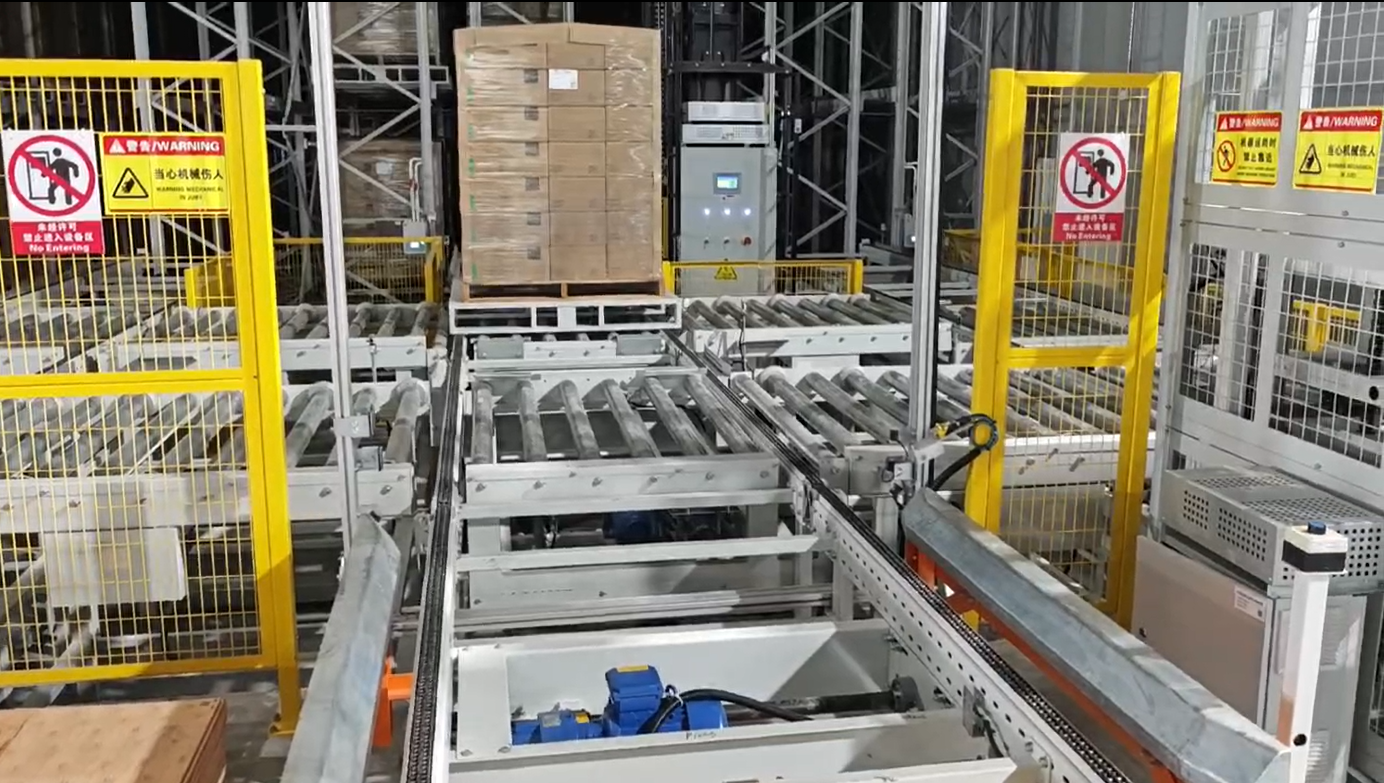

Roller Conveyor System: Utilized for its versatility in handling various types of packages and products. The roller conveyor system facilitates the seamless movement of goods across different sections of the warehouse, enhancing throughput and operational flexibility.

Transfer Machine (Shuttle System): Integrated to automate the transfer of goods between different processing stations. The transfer machine enhances efficiency by eliminating manual transfers, thereby reducing processing times and enhancing overall productivity.

Pallet Dispenser/De-stacker: Deployed to automate the pallet handling process. The pallet dispenser/de-stacker efficiently manages pallet storage and retrieval, ensuring quick access to materials and optimizing space utilization within the warehouse.

Technical Specifications

Chain Conveyor System:

- Capacity: Designed to handle up to 500 units per hour

- Speed: Adjustable from 0.3 to 1.2 meters per second

- Integration: Compatible with automated control systems for seamless operation

Roller Conveyor System:

- Load Capacity: Supports loads up to 1000 kilograms per meter

- Configuration: Gravity and powered roller options available for diverse operational needs

Transfer Machine:

- Operation: Automated shuttle system with precision positioning capabilities

- Efficiency: Reduces transfer times by up to 30% compared to manual handling methods

Pallet Dispenser/De-stacker:

- Handling Capacity: Accommodates standard pallet sizes efficiently

- Mechanism: Automated stacking and destacking operations for optimal pallet management

Project Implementation

Needs Assessment: Detailed analysis of the client's operational requirements and workflow dynamics to tailor the material handling system accordingly.

System Design: Customization of equipment layout and integration strategies to maximize space utilization and operational efficiency.

Equipment Procurement and Installation: Procurement of high-quality components and professional installation by experienced technicians to ensure seamless integration and functionality.

Testing and Optimization: Rigorous testing procedures to validate system performance and fine-tuning to meet specific operational benchmarks.

Training and Support: Comprehensive training programs for client personnel on system operation and maintenance to ensure sustainable performance and minimal downtime.

Project Outcomes

Enhanced Efficiency: Streamlined material flow and reduced cycle times improved overall operational efficiency by 25%.

Space Optimization: Efficient equipment layout and utilization strategies increased warehouse capacity utilization by 30%.

Cost Savings: Reduced labor costs and minimized product damage led to significant operational cost savings.

Client Feedback

The client expressed satisfaction with the implemented solution, highlighting improved operational efficiency and reliability. They noted our company's commitment to delivering innovative solutions tailored to their specific needs, paving the way for continued collaboration in future projects.

Conclusion

This project exemplifies our expertise in designing and integrating advanced material handling systems tailored to optimize warehouse operations. Through seamless integration of chain conveyors, roller conveyors, transfer machines, and pallet dispensers/de-stackers, we successfully enhanced operational efficiency and productivity for our client. As we continue to innovate and evolve, we remain dedicated to delivering cutting-edge solutions that meet and exceed our clients' expectations in material handling and logistics.