Inventory of 10 Automated Picking Technologies

10 Popular Picking Technologies in Modern Logistics and Warehouse Management

Selecting the right picking technology is crucial for improving efficiency and reducing costs in modern logistics and warehouse management. This article introduces 10 popular picking technologies, detailing their parameters and application scenarios to help you find the best solution for your business needs.

-

Traditional Paper Picking

- Advantages: Simple operation, low cost.

- Disadvantages: Lower efficiency, high error rate.

- Application Scenarios: Small warehouses or temporary facilities, small shipments of low-value products.

- Efficiency Parameters: Picking efficiency 35-75 lines/hour, labor cost 0.10-0.43 RMB/line.

-

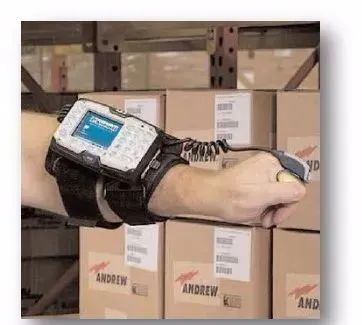

Wireless RF Picking

- Advantages: Real-time scheduling, improved accuracy.

- Disadvantages: Operation may slow due to scanning.

- Application Scenarios: Suitable for all inventory movements requiring real-time accuracy.

- Efficiency Parameters: Picking efficiency 50-75 lines/hour, labor cost 0.12-0.30 RMB/line.

-

Cart Picking

- Advantages: Pick multiple orders in one trip, increased efficiency.

- Disadvantages: Requires wider aisles, less flexible operation.

- Application Scenarios: Low to medium-speed picking environments.

- Efficiency Parameters: Picking efficiency 75-100 lines/hour, labor cost 0.115-0.20 RMB/line.

-

Pick-to-Light

- Advantages: High-speed picking, reduced walking time.

- Disadvantages: High system cost, challenging data capture.

- Application Scenarios: High-speed sorting environments.

- Efficiency Parameters: Picking efficiency 100-225 lines/hour, labor cost 0.046-0.15 RMB/line.

-

Voice Picking

- Advantages: Hands-free operation, suitable for handling heavy or bulky items.

- Disadvantages: Data transmission may slow down the picking process.

- Application Scenarios: High-speed full-case picking environments.

- Efficiency Parameters: Picking efficiency 100-175 lines/hour, labor cost 0.067-0.15 RMB/line.

-

Horizontal Carousel Picking

- Advantages: No walking time, high-density storage.

- Disadvantages: Restocking requires waiting, limited throughput.

- Application Scenarios: High-speed, high-throughput picking environments.

- Efficiency Parameters: Picking efficiency 150-350 lines/hour, labor cost 0.025-0.010 RMB/line.

-

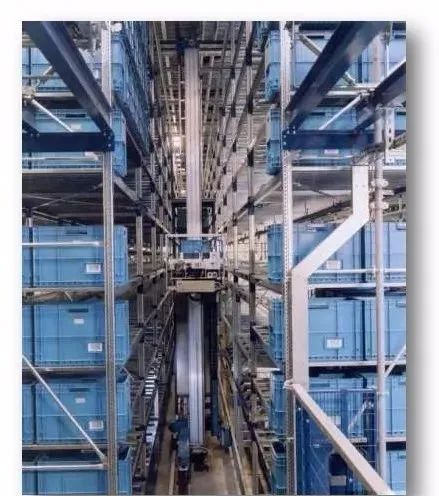

Miniload ASRS Bin Stacker

- Advantages: High-density storage, no walking time.

- Disadvantages: Limited throughput capacity, limited aisle cycles.

- Application Scenarios: Slow-moving parts requiring high-density storage.

- Efficiency Parameters: Picking efficiency 150-175 lines/hour, labor cost 0.075-0.10 RMB/line.

-

AutoStore Picking

- Advantages: No travel time, high selectivity, easy to expand.

- Disadvantages: Product height limitations, limited battery life.

- Application Scenarios: Environments requiring high-density storage.

- Efficiency Parameters: Picking efficiency 250-300 lines/hour, labor cost 0.025-0.06 RMB/line.

-

Kiva Systems Picking

- Advantages: No travel time, high selectivity, software optimization.

- Disadvantages: Market uncertainty, limited system scalability.

- Application Scenarios: Dynamic and unpredictable growth rate environments.

- Efficiency Parameters: Picking efficiency 300-500 lines/hour, labor cost 0.019-0.05 RMB/line.

-

Multi-Shuttle

- Advantages: Extremely high throughput, high productivity.

- Disadvantages: High capital investment, product size and weight limitations.

- Application Scenarios: Extremely high sorting case throughput environments.

- Efficiency Parameters: Picking efficiency 300-500 lines/hour, labor cost 0.019-0.05 RMB/line.

Conclusion

The choice of picking technology should be based on business needs, product characteristics, operating environment, and expected throughput. No single technology fits all scenarios, so understanding the advantages and limitations of each is key to selecting the right solution. Automated picking technologies often offer a higher return on investment when order volumes exceed a certain threshold.