What to Do When the Automated Logistics System Is Paralyzed?

In the modern economy, automated logistics systems are the backbone of efficient supply chain operations. However, when these systems encounter failures, they can have a severe impact on the entire supply chain.

To ensure the stable operation of logistics systems, redundancy design has become a critical strategy to enhance system reliability. We will discuss six aspects of redundancy design in detail to improve the reliability of automated logistics systems and ensure their uninterrupted operation.

1. Importance of Automated Logistics Systems

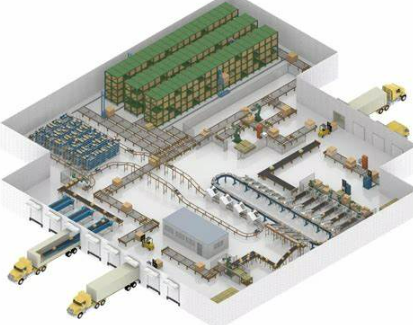

Automated logistics systems play a crucial role in the operations of intelligent warehousing systems, smart factories, and large automated logistics centers.

Many systems are quite large, involving thousands of pieces of equipment and tens of kilometers of cargo transportation lines, including various conveyors, AGVs, stacker cranes, elevators, robots, etc.

The technology is not necessarily complex, but it integrates multiple technologies and equipment. These systems typically require high integration and high reliability to support continuous operation.

2. Necessity of Redundancy Design

To ensure the stable operation of automated logistics systems, redundancy design has become a critical strategy to enhance system reliability.

Through redundancy design, key components of the system have backups, and any single point of failure will not affect the overall operation. Even if key nodes fail, the system can continue to operate through hot standby and emergency functions.

3. Six Aspects of Redundancy Design

1. Layout Redundancy

In large automated logistics systems, regionalized layout and high integration, low coupling design ensure redundancy backups for key areas.

This means that in system planning, key areas should be designed as independently operating units so that if a failure occurs in one area, other areas can continue to operate, avoiding disruptions to the entire system or logistics park operations.

2. Functional Group Redundancy

Redundancy design for components that achieve key system functions.

For example, flexible automated handling equipment can replace traditional conveyor linkage modes to improve system flexibility and reliability.

In addition, for key functional groups such as sorting equipment, multiple sets of equipment should be configured to ensure that if one set fails, another can take over the work, maintaining continuous system operation.

3. Logistics Path Redundancy

In the design of key logistics transport paths, single node design should be avoided, ensuring at least two or more paths from the source to the destination.

This way, even if one path is unusable due to equipment failure, goods can still be transported through other paths, ensuring continuity and efficiency in logistics.

4. Control System Hardware Redundancy

For key hardware components in computer systems and automated control systems, such as the CPU of programmable logic controllers (PLCs), a redundant multiprocessor structure should be used.

Thus, if one processor fails, the system can immediately switch to another processor, ensuring the stability and reliability of the control system.

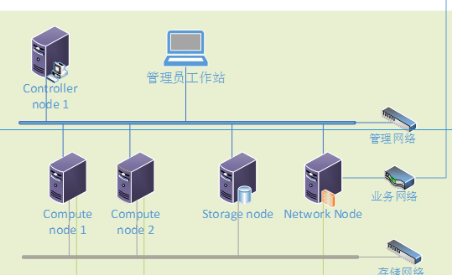

5. Support Software Redundancy

By selecting appropriate support software, clustering of computer systems can be achieved.

For example, configuring dual UPS power systems and dual power modules for servers ensures that in the event of a power failure, the system can automatically switch to backup power, avoiding system downtime due to power issues.

6. Application Software Redundancy

Application software should run in clusters of support software and undergo corresponding redundancy design.

For example, distributed caching technology can be used to replicate data in real-time, ensuring that if one node fails, other nodes can take over the work and continue processing business operations.

In addition, critical application software such as SCADA (Supervisory Control and Data Acquisition) systems should be designed for multi-node deployment, synchronizing data across multiple servers to improve system fault tolerance and stability.

4. Conclusion

By implementing redundancy design in the six aspects mentioned above, large automated logistics systems can significantly enhance their reliability and availability, achieving the goal of uninterrupted operation. This ensures the stability and efficiency of logistics systems, maximizing the economic and social benefits for stakeholders.

In emergency situations where automated logistics systems are paralyzed, these redundancy design strategies provide effective solutions to ensure the rapid recovery and continuous stable operation of logistics systems.