集成架库自动化冷库与传统自动化冷库的比较

With the rapid development of the cold chain logistics industry, the requirements for refrigerated facilities are constantly increasing. The integrated rack-and-storage intelligent automated cold storage is gradually becoming a new trend in the industry due to its efficiency, energy savings, and intelligent features.

Sharing a document that compares integrated rack-and-storage automated cold storage with traditional automated cold storage.

For the full document and more learning materials, please download from the Knowledge Planet 【Intelligent Warehousing and Logistics Technology Research Society】.

Space Utilization and Structural Advantages

The integrated rack-and-storage intelligent automated cold storage adopts an innovative steel structure design, combining the racks and the storage framework into one, effectively eliminating the structural columns in traditional cold storage. This maximizes the use of space within the warehouse.

Additionally, this structural form also has good integrity and seismic resistance, reducing the occurrence of cold bridges and providing solid assurance for the stable operation of the cold storage.

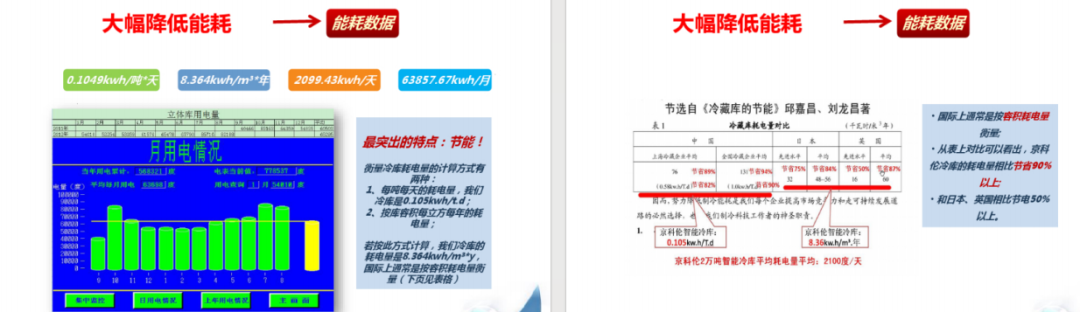

Outstanding Energy-Saving Performance

In terms of energy consumption control, the integrated rack-and-storage intelligent cold storage shows significant energy-saving effects. Compared to traditional cold storage, its power consumption is greatly reduced, with energy savings of up to 80%. This result is attributed to optimized cold storage design, including a structure without cold bridges and an efficient refrigeration system.

Insulation Performance and Durability

Insulation is another key aspect of cold storage design. The integrated rack-and-storage cold storage adopts seamless, cold-bridge-free insulation processes, effectively preventing cold air leakage and condensation issues. This also ensures the durability of the insulation layer, extending the lifespan of the cold storage.

Fully Automated Intelligent Management

Intelligence is another major feature of the integrated rack-and-storage cold storage. By integrating advanced automation control systems, the cold storage achieves full automation from refrigeration to storage management, significantly improving operational efficiency and reducing labor costs.

Investment Benefit Analysis

Compared to traditional civil engineering cold storage, the integrated rack-and-storage intelligent cold storage has significant advantages in construction and operational costs. Lower energy consumption and labor costs, combined with efficient space utilization, greatly improve the return on investment.

Comparison of Domestic and International Cold Storage Conditions

On the international stage, the integrated rack-and-storage intelligent cold storage also demonstrates its competitiveness. Compared to traditional cold storage, both domestically and internationally, it shows significant superiority in terms of power consumption, storage temperature stability, and heat transfer temperature differences.

Industry Recognition and Risk Control

The design concept and operational effectiveness of the integrated rack-and-storage intelligent cold storage have been highly recognized by the industry, representing a new benchmark in modern cold chain logistics. At the same time, strict risk control measures during project implementation ensure the reliability and stability of the project.

Conclusion

The integrated rack-and-storage intelligent automated cold storage, with its high efficiency, energy savings, intelligent management, excellent insulation performance, and significant return on investment, provides an innovative solution for the cold chain logistics industry.

With the continuous advancement of technology and the growing market demand, the integrated rack-and-storage intelligent cold storage is expected to become the mainstream choice for future cold storage construction.