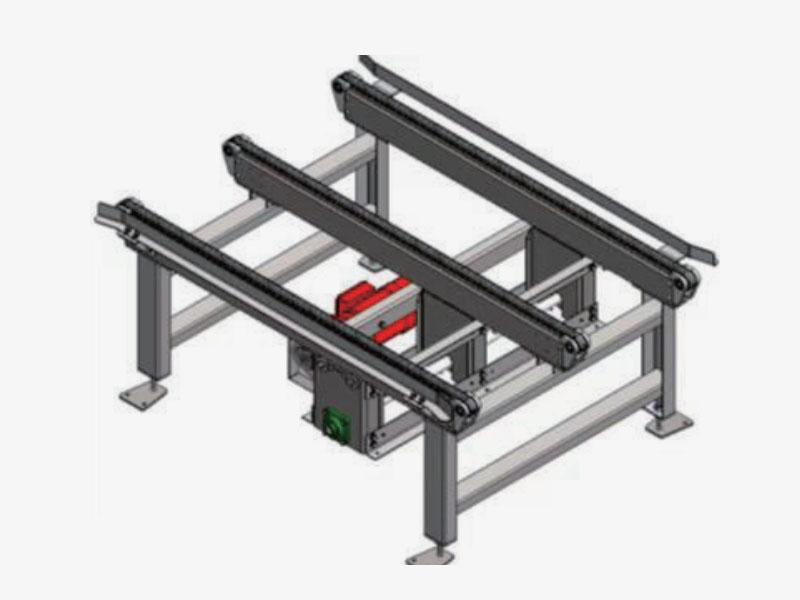

pallet conveyor design

Certainly, here are the translated versions of the design philosophies for the four types of tray conveyors:

Design Philosophy of Tray Chain Conveyorhttps://www.ssohou.com/PalletConveyorSystem/Pallet-chain-conveyor.html

The tray chain conveyor, as a vital component in material handling systems, embodies the following design philosophies:

Efficiency and Stability: The chain drive system is optimized to ensure smooth and efficient transportation of trays. High-strength, wear-resistant chain materials are selected, combined with well-designed sprockets, to improve overall transmission efficiency and service life.

Flexible Layout: Flexible conveying paths and layouts are designed based on actual production line requirements, adapting to various shapes and sizes of production spaces. Future expansion needs are also considered, with ample room for modificationhttps://www.ssohou.com/PalletConveyorSystem/Pallet-RGV.htmls.

Safety and Reliability: Multiple safety protection devices, such as emergency stop buttons and limit switches, are integrated to ensure rapid power cut-off in abnormal situations, preventing accidents. Regular maintenance and inspections of critical components ensure long-term stable operation.

-

Intelligent Control: PLC or computer control systems are introduced to automate and remotely monitor conveyor operations. Programming allows precise control over start, stop, and speed adjustments, enhancing production efficiency and flexibility.

Design Philosophy of Tray Roller Conveyor

The tray roller conveyor, renowned for its strong carrying capacity and smooth operation, embodies these design philosophies:

Rational Structure: Roller design considers material weight, dimensions, and conveying speed, ensuring optimal roller diameter, length, and spacing for efficient and stable conveying.

Low Noise and Vibration: High-precision processing and quality materials are used to minimize noise and vibration during operation, enhancing workplace comfort.

Adjustable Flexibility: Adjustable roller spacing and heights accommodate different tray sizes and weights. Multiple installation options, including horizontal, inclined, or vertical, meet various production line demands.

Ease of Maintenance: Roller conveyor components are designed for easy disassembly and replacement, reducing maintenance costs and improving efficiency. Comprehensive maintenance manuals and accessory supplies ensure long-term stable operation.

Design Philosophy of Tray RGV (Rail-Guided Vehicle)

The tray RGV, known for its high-efficiency and precise material handling, embodies these design philosophies:

High-Precision Positioning: Advanced navigation and positioning technologies, like laser guidance or magnetic strip guidance, enable precise movement and positioning on the track, ensuring accurate tray delivery.

Intelligent Scheduling: Integrated with WMS (Warehouse Management System) or MES (Manufacturing Execution System), the RGV achieves smart scheduling and route planning. Tasks are automatically assigned, and routes optimized based on production or logistics needs, enhancing overall efficiency.

Flexible Expansion: Modular and standardized RGV systems facilitate flexible expansion and upgrades based on production or logistics requirements. Multiple interfaces and protocols support easy integration with other systems or devices.

Safety and Reliability: Multiple safety protection devices and obstacle avoidance systems ensure timely detection and avoidance of obstacles and hazards during operation. Emergency stops and fault alarms ensure the safety of equipment and personnel.

Design Philosophy of Tray Elevator

The tray elevator, crucial for vertical material transport, embodies these design philosophies:

High Carrying Capacity: High-strength, rigid materials and structural designs ensure the elevator can handle various weights and sizes of trays and materials. Stability and durability are prioritized for long-term operation.

Efficiency and Energy Saving: The power system and transmission mechanism are optimized to reduce energy consumption and noise. Advanced motor and control technologies enable precise speed regulation and energy management, improving operational efficiency and energy savings.

Intelligent Control: PLC or computer control systems automate and remotely monitor elevator operations. Programming enables precise control over ascending, descending, and stopping, enhancing production efficiency and flexibility. Safety protection functions ensure safe operation.

-

Ease of Maintenance: Easy-to-disassemble and replace components simplify maintenance, reducing costs and improving efficiency. Comprehensive maintenance manuals and accessory supplies ensure long-term stable operation.

Ssohou Company mainly produces pallet conveyor and box conveyor equipment. The team has accumulated over a hundred project cases to date. Inquiries are welcome.

By the way, would you please forward this email to the right person if you are not incharge of purchase, thank you in advance!

WEB: www.ssohou.com

whatsapp:+86 13325001090

Email : sales@ssohou.com